Skunk2 Manifolds are BACK and we take a closer look...

Now that we have inventory, I've decided it's time to put one of these on the bench and take a more in-depth look at one of these power adding chunks of aluminum. These didn't last on the first round but I've got some stock to play with now (temporary coinsurance, as word spread quickly that we have them in stock).

First thing I noticed, it's two pieces? Most intake manifolds (Victor X seems to be the most comparable thing that comes to mind) are one piece. So what gives? Is this a product of an easy manufacturing trick? Nope, these feature an expandable plenum! There is a relatively vague formula out there to calculate the rough factor the plenum size has but the idea is this - More volume = bigger top end power.

There is a relatively vague formula out there to calculate the rough factor the plenum size, but the idea goes a bit like this - More volume = bigger top end power. With short runners your plenum should be 2 to 3 times the engine displacement for all out power, for response and parking lot racing (get offended), 3/4 to 1.5 times the displacement is ideal.

Right out of the box these things have proven to achieve BIG GAINS. The guys over at FM picked up in the area of 30 whp on a high output turbo setup. Naturally aspirated guys are seeing results that out perform the ever sought after European square top manifolds!

Keeping in mind the price point, we take a look at build quality. Yes, this could be better but overall, it doesn't need to be. You can see here the casting is harsh, but the important areas have been touched with a CNC machine. The runner seen here on the right is typical of what you'd see in cast aluminum and for turbo applications, completely acceptable. I hit the left runner with a ball hone for about 60 seconds and things cleaned up nicely. If you have the tools available, I'd suggest everyone do this.

Noteworthy installation bits? YES. We've sold more of these than anyone, that being the case - we've gotten the most feedback when things go wrong.

- Remove your battery terminal prior to installation, then check the clearance between your starter lead to the manifold runner. If your lead is positioned just right, it can make contact with the manifold and ground out. I've repair welded one of these manifolds because the customer didn't inspect this first (not his fault, who knew right?)

- Check the seal between the plenum and the runners. The first batch of these were assembled in what looks to be a speedy fashion and we've seen them with gaps. The later versions (currently shipping) come tight with loc tite on them already, an improvement in production is always refreshing. Snug those bolts up regardless.

- Throttle cable plate - This is not as thick as it should be. Some have figured out how to utilize the factory one but we just recommend setting the cable slack and WOT tension properly. That way, there isn't ever a situation where it bottoms out the throttle plate and pulls on the bracket.

- Throttle cable bracket bolts - these go all the way through the plenum wall, so there is a possibility they can leak air, a bit of RTV on the bolt threads can solve this.

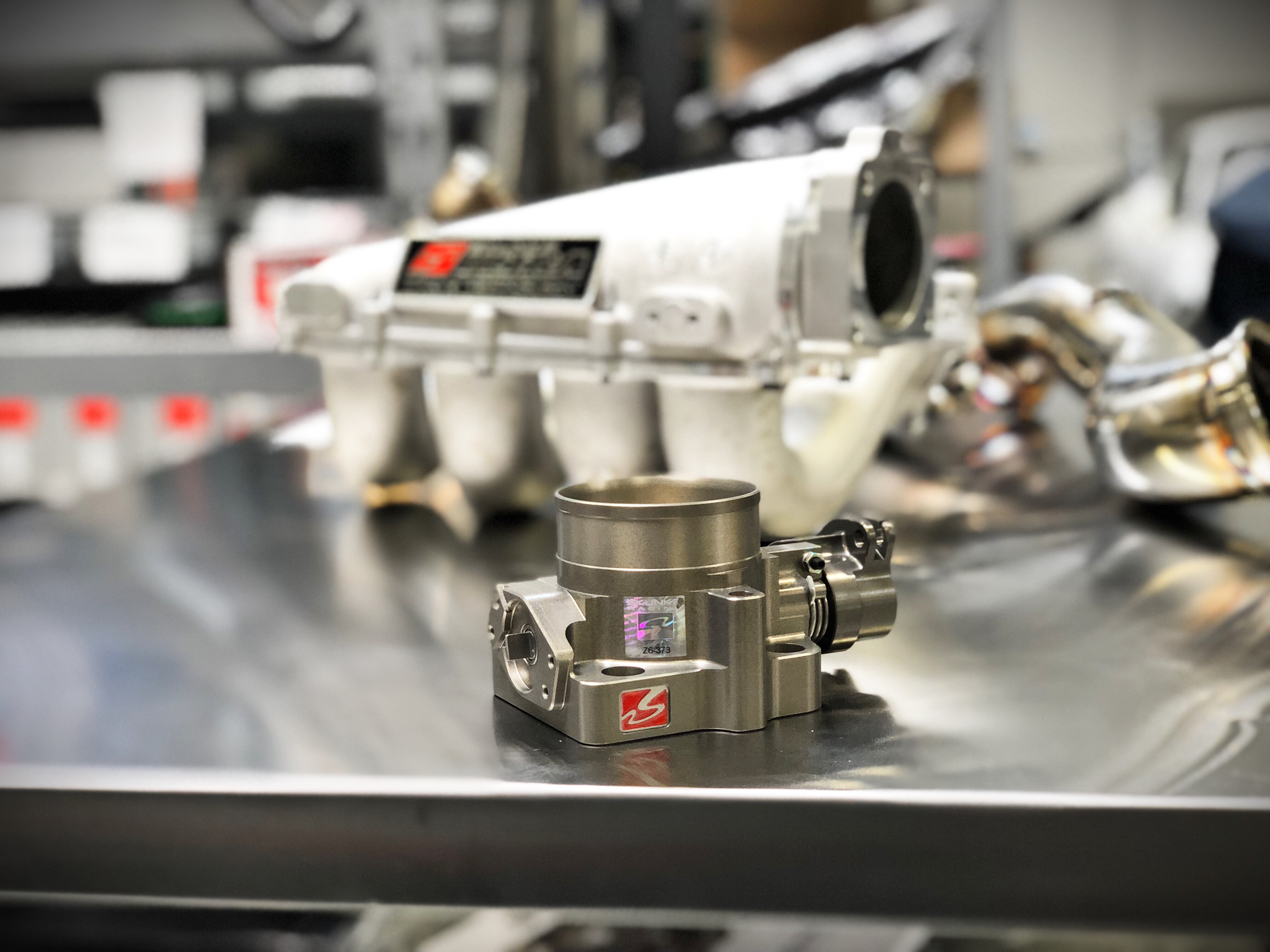

Also, the Skunk2 Throttle body is a nice touch. I don't know that there are huge benefits on a naturally aspirated configuration but it looks sharp, the throttle plate bar won't break (known issue on the BP engines) and with your fancy new intake manifold, you won't need to do any gasket matching to achieve full flow.